As far as I know, there are no perfect 3D scanning tools. And, that is most definitely true when it comes to sub-$1,500 scanners. But, that has never stopped new users from prematurely declaring this or that scanner is 'junk' or 'useless'.

I was reminded of this recently as I explored a web site for uloading scanned or captured images. There was a scan of an object that appeared quite good to me, having seen the results from dozens of scanners over at least 6+ years. But, it was disheartening to see the person uploading the image to seem to be utterly disappointed by the result. I can only guess that they were expecting perfection from their new scanner right out of the box and, in my experience, that is laudable; but, totally unrealistic expectation.

The All Too Often Sad Outcomes of Unrealistic Expectations

I am not going to post an image of the object because my purpose is not to offend, or even criticize this user. In fact, my issue with their position isn't that they do not tkink the scanner they have is adequate; but, that an expectation of perfection can often be an impediment to success and fulfillment.

Back in what many would consider to be the dark ages, I was a teacher of middle school students over several years. One of my most promising students was also my most frustrating student. If this student did not get 100% on a test, they angrily tore their paper up in little pieces. 99% was completely unacceptable.

I have watched this person over the years and have seen the devastation this has had on both their personal and professional life. Who could hope to have a long term relationship with a person that demands perfection in all things. And, in spite of the fact that this person clearly had the intellectual capabilities of doing great things, that has not been the case in the real world of work.

The Abrupt End of Growth and Discovery

My heart sank as the user declared they were probably sending back the scanner, which I know to be one of the best in its price range. One reason for my lamenting that decision is that I new, from experience, based on what I could see in the scan, that none of the competitors in that price range was going to do any better. Now, to be fair, I do not know their ultimate reason for thinking they need a super-high quality scanner. In fact, for their intended purpose they actually may need an ultra-high resolution scanner well beyond anything moost of us need in the classroom. But, if so, they had better be prepared to spend tens of thousands of dollars for one.

But, even then, I have the sneaking suspician that this user would be less than impressed by the output from the best professional scanner right out of the box. As far as I am aware, the results from ALL scanners require some level of post-processing to achieve anything close to perfection.

In every case, what is likely to happen is that a new scanner is purchased, tried and found wanting only to be returned without any real effort to understand the tool's true capabilities. An unrealistic expectation allow a person to dismiss a product too prematurely without any real commitment to getting the most out of it.

And, that is a shame... because, the journey usually has the potential to be even more valuable than the outcome. When we make a commitment to fully understanding a tool, the adventure can take us into many directions. In the case of scanning, that can be coming up with special lighting solutions or, in the case of scanners using a turntable, a more indepth study of the object being scanned to overcome design limitations that hinders the scanning function.

Bringing Expectations into the Realm of Reality

The first place I would look for a dose of reality is our ultimate purpose, educationally, for scanning. In the scope of this blog, that is to use the capturing process as a starting place for observation and research. While we want the best representation possible, within the means at our disposal, the actual capture need not be absolutely perfect to be of enormous value to our students and the community.

So, in fact, it matters little if we use Qlone on a smart phone or a $25,000 scanner. Both are a means to and end and the bottom line is that all we need to do is focus on learning to use what we have to get the best result possible given our circumstances.

If we have no means to scan, we need to find the best we can find within our budget. If we have a scanner, however crude it may appear to be, we need to focus on getting the most out of it. And, all this has to be done with the realization that some things are going to work better than others and that disappointment is NOT a show-stopper. It is an opportunity to learn and grow.

I have spent the past few weeks using a single scanner focusing on capturing objects purposely chosen to challenge both the equipment and myself. In the process, the challenges have driven me to come up with new lighting techniques specific to this scanner and learning an all new image processing program that can help deal with the specular nature of the objects themselves. I'm very pleased with where we are now in our understanding of this scanner. But, I know there is more to learn.

But, now, I will be going back to some older scanners we've owned for years to see how they fare with these same objects. Though I have extensive experience over the years with these scanners, what is different this time is that I bring what I have recently learned with the most recent scanner. While it may or may not help for any given scanner, it certainly enhances the probability of improving the outcomes with each scanner even if it's only a starting point for a new quest to discover a different lighting strategy. But, if I were to bring unrealistic expectations for any of these tools to the table it bring all exploration to an abrupt end. And, that is the worst outcome of all.

P.S. Recently, I picked up an HP Z 3D scanner to test and immediately tried using it. Quite frankly, while I don't think my expectations were too high, since I have an HP RealSense scanner tablet, it was difficult to keep from losing tracking. Not wanting to give up, I contacted the product manager and learned it had been discontinued. And, the reason for that was that HP, too, realized it was difficult to use. Creating a 3D scanner that is user friendly is NOT easy. And, the fact that a huge company like HP found it difficult to pull off to their satisfaction should say something about how truly difficult it is. Even so, while the HP is now lower on the priority list, it is still a tool we plan to pursue to try to learn because when it does work, it is gorgeous. We don't like tools going to waste!

Tuesday, January 28, 2020

Friday, January 24, 2020

Being a Student Museum Conservator

When creating a "Virtual Museum" in the classroom, we begin by scanning actual 3D objects of some present or future historical value. For the time that we may have these items students will have to understand the role of the Museum Conservator.

For items in our possession for a short time, our conservatorship involves how items are handled. For items under our student's control for a longer time, it also includes how they are displayed and/or stored.

We previously posted an image of two Santa containers. One is clearly in a LOT better shape than the other.

A 3rd Cheinco Santa arrived today and together with the others perfectly illustrates the cumulative affects of various states of poor storage.

The Santa on the left of both images was clearly stored in a more protective environment than the other two. And, the one on the right clearly shows evidence of very poor storage conditions. This is the natural fate of ALL objects. So, conservators pay a LOT of attention to how they protect items both on display and in storage.

This fact is another reason why working with real objects to capture and turn into virtual objects has such great educational value. It not only provides an opportunity to focus on all the related aspects of the life of an object; but, also provides a point of departure into related subjects such as the affect of light and heat on objects over time.

When I get to introduce our Santas to our students, there are many questions I want to ask them before we even begin to try to capture them. Why, for instance, is the Santa on the right lighter on top than on the bottom? What might that tell us about its life since it was created? Etc., Etc., Etc.

The point is that 3D Scanning is MORE than a single, isolated function. If seen correctly, it can become an adventure that leads in many directions... including, perhaps, a career as a conservator in one of the world's great museums!

Look closely at what this Getty Museum conservator is doing!

For items in our possession for a short time, our conservatorship involves how items are handled. For items under our student's control for a longer time, it also includes how they are displayed and/or stored.

We previously posted an image of two Santa containers. One is clearly in a LOT better shape than the other.

|

| Two Cheinco Santas Demonstrating Storage Damage |

A 3rd Cheinco Santa arrived today and together with the others perfectly illustrates the cumulative affects of various states of poor storage.

|

| Three Cheinco Santas Demonstrating Cumulative Storage Damage. |

The Santa on the left of both images was clearly stored in a more protective environment than the other two. And, the one on the right clearly shows evidence of very poor storage conditions. This is the natural fate of ALL objects. So, conservators pay a LOT of attention to how they protect items both on display and in storage.

This fact is another reason why working with real objects to capture and turn into virtual objects has such great educational value. It not only provides an opportunity to focus on all the related aspects of the life of an object; but, also provides a point of departure into related subjects such as the affect of light and heat on objects over time.

When I get to introduce our Santas to our students, there are many questions I want to ask them before we even begin to try to capture them. Why, for instance, is the Santa on the right lighter on top than on the bottom? What might that tell us about its life since it was created? Etc., Etc., Etc.

The point is that 3D Scanning is MORE than a single, isolated function. If seen correctly, it can become an adventure that leads in many directions... including, perhaps, a career as a conservator in one of the world's great museums!

Look closely at what this Getty Museum conservator is doing!

|

| Scanning an Object at the Getty Museum |

Thursday, January 23, 2020

Michael Cruze: A fourth Grade Student That Gets it!

Imagine my delight as I opened the paper and found a story about a fourth grade student that LOVES antiques and the Antique Road Show! He is Michael Cruz, a student at Carrol Lutheran School in Westminster, MD.

Here is the story

This EXACTLY what we hope for EVERY student... an appreciation of history through history's tools and objects made by and used by people in the past.

For now, I will let the story speak for itself. So, please click on the link to the story and pay special attention to the photo showing his collection of family heirlooms.

At some point I hope to interview Michael. But, for now, what I hope that what you take away from the story is that appreciation of antiques isn't just for old people looking for an investment or reliving their own past. It's about people of any age that realize that objects from the past, even a recent past, can tell us something about us, our times and what got us here.

Michael get's what it takes to be a 'curator' of a collection that, along with his photos, in and of itself provides the stories and context behind them. That is VERY cool!

Here is the story

This EXACTLY what we hope for EVERY student... an appreciation of history through history's tools and objects made by and used by people in the past.

For now, I will let the story speak for itself. So, please click on the link to the story and pay special attention to the photo showing his collection of family heirlooms.

At some point I hope to interview Michael. But, for now, what I hope that what you take away from the story is that appreciation of antiques isn't just for old people looking for an investment or reliving their own past. It's about people of any age that realize that objects from the past, even a recent past, can tell us something about us, our times and what got us here.

Michael get's what it takes to be a 'curator' of a collection that, along with his photos, in and of itself provides the stories and context behind them. That is VERY cool!

Tuesday, January 21, 2020

An Example of WHY Capturing is Important to History

As my first example of a classroom "Curated Virtual Museum Collection" I chose a series of objects that one can buy for less than $20. They aren't all that expensive nor rare... for now. Here is a sample.

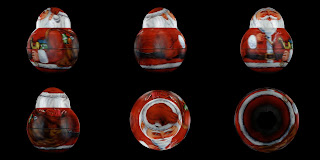

The Matter and Form scanner did an excellent job of capturing this object with a single 'Quick Scan'. The result will be even better when I add a second scan directed at capturing the top and bottom. But, even if scanned flawlessly, the question remains. Why pick this object as an example of preserving history.

The answer is TIME and LIGHT. Right now we can find very nice examples of this object on eBay or Etsy. But, like ALL things, time and light, have a way of taking away this luxury. In fact, I have not one; but, TWO examples of the Santa. They were probably created around the very same time. However, today, just under 40 years later, they look VERY different.

It is obvious from this photo that the Santa on the right has been sitting in a well-lit spot over an extended period of time. And, that leads us to believe that the Santa on the left could face that very same fate given enough time if not well protected.

The ratio of perfect examples as compared to less-than-perfect examples inevitably changes over time. When they first came off the for there were more prefect than not. But, as the years roll by there will eventually be more damaged than perfect. In fact, the Santa on the left is actually LESS perfect now than when I first received it due to my carelessness. There is a small dent near the bottom in the back caused by my picking it up by the head not realizing that the head slides off easily.

These objects represent the work of a company of around 600 people working at Cheinco, in the small town of Burlington, New Jersey. (By the way, if you ever get by that way, the Burlington County Historical Society has some toys and other items created by Cheinco.)

It's hard to imagine that any company in the future would resume the production of tin objects like this when plastic is so prevalent and inexpensive. Therefore, they represent a snapshot in time that will probably never exist again.

By scanning these objects in the best condition possible, as faithfully as possible, we can capture that history for others to see and appreciate in a very tangible way. We can't duplicate the tin; but, we can duplicate the overall effect of the design on the tin and capture some of the documentation, such as the printing on the bottom that gives us some clues about the maker.

Perhaps, even immediately MORE importantly, the scanning and curation process encourages us to know more about the item, more about the company and more about the people that worked in that factory. We are, in effect, also capturing a day in THEIR life. And, that is very, very cool.

Should a descendent, long into the future, want to know more about what their ancestor did in 1980, the virtual museum exhibit will be there waiting for them long after ALL the tin objects have faded like Santa #2.

And, that is justification enough. :)

P.S. If you clicked on any of the links in this page, you have experienced another benefit of our having selected the Cheinco tins as our example. Would you really have visited the Cheino article, the Burlington, NJ pages or the Burlington County Historical site had we not written about our Santa? Yes, it is true. 3D Motivates!

|

| Chienco Santa - Tobacco Tin circa 1980 |

The answer is TIME and LIGHT. Right now we can find very nice examples of this object on eBay or Etsy. But, like ALL things, time and light, have a way of taking away this luxury. In fact, I have not one; but, TWO examples of the Santa. They were probably created around the very same time. However, today, just under 40 years later, they look VERY different.

|

| Time and Lack of Care Ravage a Santa |

The ratio of perfect examples as compared to less-than-perfect examples inevitably changes over time. When they first came off the for there were more prefect than not. But, as the years roll by there will eventually be more damaged than perfect. In fact, the Santa on the left is actually LESS perfect now than when I first received it due to my carelessness. There is a small dent near the bottom in the back caused by my picking it up by the head not realizing that the head slides off easily.

These objects represent the work of a company of around 600 people working at Cheinco, in the small town of Burlington, New Jersey. (By the way, if you ever get by that way, the Burlington County Historical Society has some toys and other items created by Cheinco.)

It's hard to imagine that any company in the future would resume the production of tin objects like this when plastic is so prevalent and inexpensive. Therefore, they represent a snapshot in time that will probably never exist again.

By scanning these objects in the best condition possible, as faithfully as possible, we can capture that history for others to see and appreciate in a very tangible way. We can't duplicate the tin; but, we can duplicate the overall effect of the design on the tin and capture some of the documentation, such as the printing on the bottom that gives us some clues about the maker.

Perhaps, even immediately MORE importantly, the scanning and curation process encourages us to know more about the item, more about the company and more about the people that worked in that factory. We are, in effect, also capturing a day in THEIR life. And, that is very, very cool.

Should a descendent, long into the future, want to know more about what their ancestor did in 1980, the virtual museum exhibit will be there waiting for them long after ALL the tin objects have faded like Santa #2.

P.S. If you clicked on any of the links in this page, you have experienced another benefit of our having selected the Cheinco tins as our example. Would you really have visited the Cheino article, the Burlington, NJ pages or the Burlington County Historical site had we not written about our Santa? Yes, it is true. 3D Motivates!

Saturday, January 18, 2020

3D Scanning Workflow - Step #1 UPDATE: Material File Correction

While I am still no expert in Affinity Photo, a few lessons by by Ezra and Ally of Affinity Revolution have been VERY helpful!

At first, i thought I could solve the overly bright issues in some areas by a simple color replacement. I was sweating bullets when I realized that the Color Replacement Tool in Affinity ALWAYS respects the underlying brightness value. This great for changing a shirt from one color to another because the features like folds and shadows remain. But, it is NOT so great when you want to turn bright red to darker red.

Fortunately, I enrolled in the free "Magically Remove Shadows" online course. It turns out that the process of removing shadows can be helpful in reducing glare as well. My stab at it isn't perfect. But, it DOES show me that I'm on the right track and that my gut feeling that Affinity Photo is the right tool for the job has been validated.

So, lets compare the BEFORE and AFTER. First the FRONT view.

As is plain, Affinity Photo was able to reduce the affects of glare considerably! The most important part of this transformation is that if I should want to try using the Color Replacement Tool, the undying tonality will help match the final colors better.

Now for the BACK view.

This area is a bit less successful. That is probably because I applied the corrections uniformly across all the images and that's probably NOT the best strategy. But, I was anxious to show some results.

The great thing is that like MF Studio and the Matter and form scanner, we can go back into an Affinity Photo project and refine it. But, even at this stage I think that the concept of improving color captures by editing a mesh in a photo image application has been well demonstrated.

Lastly, here is a comparison of the two mesh files.followed by BevelPix links where you can see the objects in full 3D.

And the BevelPix.com links:

https://bevelpix.com/creations/5e153984761dfe666220896d

https://bevelpix.com/creations/5e23711c1265aed1ecc4ed8c

The takeaway from this post is that capturing does not have to be, nor should it be, a one-step process. Learning to take advantage of other tools to create an improvement WORKFLOW is an important skill to use.

At first, i thought I could solve the overly bright issues in some areas by a simple color replacement. I was sweating bullets when I realized that the Color Replacement Tool in Affinity ALWAYS respects the underlying brightness value. This great for changing a shirt from one color to another because the features like folds and shadows remain. But, it is NOT so great when you want to turn bright red to darker red.

Fortunately, I enrolled in the free "Magically Remove Shadows" online course. It turns out that the process of removing shadows can be helpful in reducing glare as well. My stab at it isn't perfect. But, it DOES show me that I'm on the right track and that my gut feeling that Affinity Photo is the right tool for the job has been validated.

So, lets compare the BEFORE and AFTER. First the FRONT view.

|

| Santa Front - Before Editing Mesh in Affinity |

| |

| Santa Front - After Editing Mesh in Affinity |

Now for the BACK view.

|

| Santa Back - Before Editing Mesh in Affinity Photo |

|

| Santa Back - After Editing Mesh in Affinity Photo |

The great thing is that like MF Studio and the Matter and form scanner, we can go back into an Affinity Photo project and refine it. But, even at this stage I think that the concept of improving color captures by editing a mesh in a photo image application has been well demonstrated.

Lastly, here is a comparison of the two mesh files.followed by BevelPix links where you can see the objects in full 3D.

|

| Santa Mesh File - Before Editing Mesh in Affinity Photo |

|

| Santa Mesh File - After Editing Mesh in Affinity Photo |

https://bevelpix.com/creations/5e153984761dfe666220896d

https://bevelpix.com/creations/5e23711c1265aed1ecc4ed8c

The takeaway from this post is that capturing does not have to be, nor should it be, a one-step process. Learning to take advantage of other tools to create an improvement WORKFLOW is an important skill to use.

Friday, January 17, 2020

3D Scanning Workflow - Step #1: Material File Correction

Nothing could be farther from the truth.

There is a LOT that can be done with a capture that may seem unacceptable. But, to turn that capture into some usable there may be a bit of processing that needs to be applied. We're going to call this "The 3D Capture Workflow" and it will involve one or more post-processing steps.

While capture devices and software often allow several file types to be created, the most common from which to start is the Alias Wavefront Object or .OBJ file type. The primary saved file will often have one or more child files, usually .MTL and .JPG (or .PNG).

ALIAS WAVEFRONT OBJECT FILE (.OBJ)

We usually open an .OBJ file in a 3D viewer application. The result is something like this... a color 3D object that can be rotated or viewed from all sides.

|

| Santa Capture Viewed in Meshlab |

But, the .OBJ file is actually a text document that can be opened in any text editor. It primarily contains all of the "Vertex Position" data which defines the underlying SHAPE of the captured object. And, it also contains a pointer to the MESH MATERIAL file. Here are the first few lines of our sample .OBJ file.

# File produced by Open Asset Import Library (http://www.assimp.sf.net)In this case the child material file is called "SantaTest01.mtl". Let's take a look at that file.

# (assimp v4.1.0)

mtllib SantaTest01.mtl

# 57085 vertex positions

v -6.74224853515625 52.62289428710938 -80.77588653564453

v -6.03680419921875 52.62289428710938 -80.8377685546875

v .....

MESH MATERIAL DEFINITION FILE (.MTL)

Like the .OBJ file, the .MTL file is a text file. It's basic purpose is to point to one or more image files that define the color information that provides the object with a color surface.

# File produced by Open Asset Import Library (http://www.assimp.sf.net)In this case, there is only one child image file that is called "SantaTest01.jpg". It is this file that we will be focusing on for the first step of our post-processing workflow.

# (assimp v4.1.0)

newmtl SantaTest01_material

illum 1

map_Kd SantaTest01.jpg

COLOR MESH MAP FILE (.JPG)

What provides the color detail of our 3D object is actually a flat image file. Before viewing the .JPG, let's revisit our capture from a different angle.

|

| Santa Capture - Back View |

The other issue, as pointed out by the green arrow, is that is a seam in an area where there is no such seam in the original object. while not a 'show stopper', if we can learn how to diminish the affect of that seam, we can obtain a better final result.

To understand and fix (or at least improve) both of these issues, let's turn to the Mesh Map file... SantaTest01.jpg.

|

| SantaTest01.jpg Mesh Map File |

AFFINITY PHOTO / AFFINITY DESIGNER

Any image processing application could be used. But, I have chosen to use Affinity Photo for this purpose. The reason for choosing this application is two-fold. First, it is VERY reasonable in cost... just $49.99. And, it is amazingly complete is terms of matching the much more expensive Adobe Photoshop. Secondly, while I am a complete novice at using Affinity Photo, I have found some amazingly easy lessons that should let me get up to speed enough at least well enough to improve this image and, consequently, improve the overall result of the capture.

The Affinity team has create a number of great free tutorials available on their web site and/or YouTube. But, the training potential also extends to 3rd party experts like Ally and Ezra Anderson of Affinity Revolution training company.

AFFINITY REVOLUTION TRAINING COURSES

Affinity Revolution has a number of terrific free training videos on their YouTube channel. I have seen enough to believe that, using their training, I will be able to become proficient enough to be able to significantly improve any capture.

Yes, I realize revealing my ignorance in product that I intend to rely on not only for myself; but, others, may be more than a bit foolish. So, let me explain how I came to this place. While I started out, decades ago, as an Adobe user, I was never really a fan. When I came upon an image application called PhotoImpact, I immediately adopted it as my goto image processing program.

Unfortunately, Ulead, the original company that produced PhotoImpact went out of business and sold the rights to Corel who has never updated the product and it became simply too buggy in the new operating versions to remain with it. I have tried many other candidates over the last ten years and none of them were impressive enough to make the switch until I recently found Affinity.

So, it's not as if I am starting from scratch. I know what has to be done. I simply have to become familiar with the ways Affinity offers to do it. And, I am confident enough in the training options available that sooner (I hope) or later I can fix the above image enough to be able to point out how to do so to those wanting to fix their own captures.

The positive thing is that if it turns out to be SOONER, rather than LATER, you should be convinced that Affinity products (either Affinity Photo or Affinity Designer) can do the same for you. It's a gamble that I find worth taking. So, I plan on seeing a lot of Ally or Ezra over the next few days.

The other positive I hope that comes from revealing my 'newbie' status with Affinity is that everyone that reads this will understand that at some point in our journey ALL of use are 'newbies' and especially if we have any sense of adventure and/or curiosity in trying to better our lives and find new tools. The fun is in seeing how fast we can leave our 'newbie' status behind us to become as proficient as we have to be in order to accomplish our goals.

Let the adventure begin!

Wednesday, January 15, 2020

HP Z 3D Scanner: A Discontinued Trail Blazer

I came late to the party when it came to discovering the HP Z 3D Scanner. In fact, it had probably been discontinued by the time I ordered one.

Normally, that could only be described as a bummer.

And, the fact that it was a bit picky about what it could actually scan might normally be viewed as a HUGE BUMMER.

But, I don't see it that way.

And, the reason I don't see it that way is because I appreciate what they tried to do and understand, at least at a basic level, why it was so difficult to achieve.

Here is the link to the HP pages for the HP Z 3D Scanner.

https://www8.hp.com/us/en/workstations/z-3d-camera.html

What HP tried to do was create an integrated multi-purpose camera system with a 3D scanning capability. What made this capability special was that one held the object to be scanned and rotated it in all directions for the capture. All traces of the hand holding the object would be removed in the final outcome.

When you think about it, this was a brilliant strategy for capturing smaller objects. And, from an educational standpoint it was doubly brilliant. For, not only did the person scanning have direct tactile contact with the object being scanned; but, was in direct control of the orientation of the object in a way that ensured full coverage like no other technique could accomplish.

Unfortunately, there were issues with tracking that defeated the goals of the project.

What a shame. Because the goals were and ARE not only laudable; but, precisely the kind of thing that makes 3D scanning so useful for students needing different approaches to learning. Every brain is different and the tactile nature of the HP Z's scanning strategy offered a potentially different route for brains benefiting from touch and feel.

I certainly hope HP's engineers do not give up on 3D scanning that includes the ability for the user to pick up, rotate and manipulate the object being studies and scanned. Frankly, I would much rather move an object than move a scanner. So, I am not at all bothered by the fact that my purchase, for now, is going nowhere. It provided me with a glimpse of a new strategy that I can fully appreciate and I think the engineers behind it should be give a great deal of credit for the effort.

Sooner or later, I KNOW that what they envisioned will be possible. And, I hope it is sooner, rather than later.

Normally, that could only be described as a bummer.

And, the fact that it was a bit picky about what it could actually scan might normally be viewed as a HUGE BUMMER.

But, I don't see it that way.

And, the reason I don't see it that way is because I appreciate what they tried to do and understand, at least at a basic level, why it was so difficult to achieve.

Here is the link to the HP pages for the HP Z 3D Scanner.

https://www8.hp.com/us/en/workstations/z-3d-camera.html

What HP tried to do was create an integrated multi-purpose camera system with a 3D scanning capability. What made this capability special was that one held the object to be scanned and rotated it in all directions for the capture. All traces of the hand holding the object would be removed in the final outcome.

When you think about it, this was a brilliant strategy for capturing smaller objects. And, from an educational standpoint it was doubly brilliant. For, not only did the person scanning have direct tactile contact with the object being scanned; but, was in direct control of the orientation of the object in a way that ensured full coverage like no other technique could accomplish.

Unfortunately, there were issues with tracking that defeated the goals of the project.

What a shame. Because the goals were and ARE not only laudable; but, precisely the kind of thing that makes 3D scanning so useful for students needing different approaches to learning. Every brain is different and the tactile nature of the HP Z's scanning strategy offered a potentially different route for brains benefiting from touch and feel.

I certainly hope HP's engineers do not give up on 3D scanning that includes the ability for the user to pick up, rotate and manipulate the object being studies and scanned. Frankly, I would much rather move an object than move a scanner. So, I am not at all bothered by the fact that my purchase, for now, is going nowhere. It provided me with a glimpse of a new strategy that I can fully appreciate and I think the engineers behind it should be give a great deal of credit for the effort.

Sooner or later, I KNOW that what they envisioned will be possible. And, I hope it is sooner, rather than later.

Tuesday, January 7, 2020

The Matter and Form 3D Scanner for the Classroom

As much as I love what learning 3D design and printing can do for students, especially at-risk students, I know that there is one huge impediment to widespread adoption of 3D printing in the classroom beyond the narrow focus of STEM and robotics. And, that is the fundamental nature of the FDM printer being used in schools today.

As cool as they are, they are simply too slow and too prone to failures for a teacher to rely on for serving a full classroom of students. Thus, they are being relegated to specific tasks to support small groups of students like those in the robotics club, etc. Even in the situation in the classes using our curriculum, which are generally limited in size, it is a struggle for our teachers to get everything printed from week to week. So, we understand the issues teachers face.

But, we continue to be adamant in our belief that 3D technologies offer ALL students unique learning opportunities. And, that is why we are so excited about 3D capture in all its forms... 3D scanning or photogrammetry. And, while we can envision many positive educational opportunities in all classroom subjects, history is a great place to start on a grand adventure.

A Matter and Form 3D Scanner Adventure

A little over a month ago, we learned about the Matter and form 3D scanner. It was just before our one week 3D ThinkLink Immersion class for deserving Cadets from 3 Youth ChalleNGe sites (DC, MD and SC). Thus, we were able to obtain a Matter and Form 3D scanner just in time for the class.

It is completely different from all the other handheld scanners we own and use. And, quite frankly, that difference stood in the way of our being able to immediately use it for the class as we had hoped. Even so, we realized we had something very different and very special in terms of our long-term goals of encouraging teachers to consider enhancing their history curriculum by creating their own "Virtual Museums" in the classroom.

So, I have spent a great deal of time since then to learn all I can about what the Matter and Form 3D scanner has to offer. And, it not only measures up to my hopes; but, significantly exceeds my expectations. And, I DO mean SIGNIFICANTLY!

Two Basic Differences

We have enjoyed all the handheld 3D scanners we own. They include the Sense 1 and Sense 2, the xyzPrinting 3D scanner, four standalone Intel iSense scanners, an HP Notebook with a built-in Intel iSense Scanner and the newer HP Z 3D Scanner. Beyond computer based scanning, our experience also expands to a Sony Xperia XZ1, which is terrific for scanning people and several iPhone and iPad apps. Every one of them is useful at some level.

But, the Matter and Form is totally unique in TWO important differences.

Difference 1: Control, Control and Control!

I mentioned earlier that we were not, initially, able to immediately benefit by obtaining the Matter and Form 3D scanner in time for our 3D Immersion Week. That is because that week is packed with all new experiences for our cadets and it appeared that scanning with the Matter and Form was going to be a long process.

What I didn't know at the time is that how long a scan takes is under OUR control. It's simply a matter of trading speed for higher "Point Cloud" resolution.

All full color 3D scans consist of a Point Cloud that controls the underlying shape and the color image called a 'Material'. One set of cameras captures the point cloud and another captures the color image covering the final rendered object.

Here is an example of the "Point cloud". (Note also multiple test scans listed to the left of the MF Studio screen.)

And , here is an example of the "Mesh" material applied.

With the Matter and Form scanning system, just about every aspect of the process is under the user's control. Had I known at the time, we could have easily reduced scanning time significantly with only a little loss of fidelity. Each of the scans in the list in the first image represent quite different scan times. The larger the number, the less the time. The trade-off is less density and lower base object resolution. We'll be going into this in detail in future articles. The important take-away is that, unlike my initial impression, we CAN scan very quickly if we desire.

Difference 2: Iterative Scanning (Adding scans to improve coverage and quality)

Secondly, scanning is NOT limited to a single all-or-nothing pass. This HUGE! If you have ever used a handheld 3D scanner you, too, have had the experience of trying to capture everything in a single session hoping that one false move doesn't throw you into the frustrations of the "Lost Tracking" wilderness! Even when successful, we are rarely able to scan ALL 3D sides of an object with a 3D scanner in a single scan. In fact, I don't recall a single instance of having been able to do so until obtaining the HP Z 3D scanner. (But, experience with the HP Z scanner, while so promising, has been initially frustrating in that once tracking is lost, it seems very difficult to recover.)

The Matter and Form's software, however, not only allows for multiple scans using different orientations; but, in most cases, easily merges those scans into a single 3D virtual object. And, you don't even have to do those scans in the same session. We can come back to a saved scan project at any time and add additional scans as we learn more and get better at it. In fact, all of the sample scans I am going to use in this article represent a single scan just to show scan quality. And, in every case, we plan to return to the each of the projects to add additional scans using different orientations to complete the project by adding the top and bottom to the scan list.

We can choose any of the scans or a mix of scans to produce our final result.

Why Our Selected Test Objects Are Important

At this point, I should point out why we are beginning our exploration of all of our scanners with the particular objects we have chosen. After all, tobacco tins aren't exactly an obvious choice. And, neither are the upcoming Sponge Bob Square Pants fish tank ornaments. As unlikely as it may seem they do have two things in common. First, both groups of objects can form 'curated collections'. We will not only scan one tobacco tin; but, multiple tobacco tins dating from the early 1900s. Here is just one example:

And, while Sponge Bob Square Pants fish tank ornaments are still being sold; they, too, form a historic collection, albeit a modern one, that will eventually pass away as the future moves on to other cultural icons.

History is a continuum. So, like the visionary Dr. Henry Chapman Mercer, we want all of our students to understand that what is common today may become VERY rare in the not-to-distant future.

The other thing they have in common, although for different reasons, is that they are difficult to scan.

In fact, I suspect that none of the handheld scanners will be able to capture the tobacco tin sample above. That is because the underlying shape of these uniformly round tins are too smooth. Distinctive features work best for hand held scanners.

The Sponge Bob figures present their own challenges that will require multiple scans using different orientations and locations on the turntable to derive a complete capture with the Matter and Form 3D scanner and should be a challenge for our handheld scanners as well.

Highly Recommend Considering a Matter and Form

This was not intended to be a 'review'. It's simply an introduction to the scanner I will be using in our initial 'Virtual Museum' articles. Even so, I cannot conclude this article without issuing a hearty recommendation for the Matter and Form 3D scanner and hope that you will continue to follow our progress to see why I like it so much.

As cool as they are, they are simply too slow and too prone to failures for a teacher to rely on for serving a full classroom of students. Thus, they are being relegated to specific tasks to support small groups of students like those in the robotics club, etc. Even in the situation in the classes using our curriculum, which are generally limited in size, it is a struggle for our teachers to get everything printed from week to week. So, we understand the issues teachers face.

But, we continue to be adamant in our belief that 3D technologies offer ALL students unique learning opportunities. And, that is why we are so excited about 3D capture in all its forms... 3D scanning or photogrammetry. And, while we can envision many positive educational opportunities in all classroom subjects, history is a great place to start on a grand adventure.

A Matter and Form 3D Scanner Adventure

A little over a month ago, we learned about the Matter and form 3D scanner. It was just before our one week 3D ThinkLink Immersion class for deserving Cadets from 3 Youth ChalleNGe sites (DC, MD and SC). Thus, we were able to obtain a Matter and Form 3D scanner just in time for the class.

|

| Matter and Form 3D Scanner |

So, I have spent a great deal of time since then to learn all I can about what the Matter and Form 3D scanner has to offer. And, it not only measures up to my hopes; but, significantly exceeds my expectations. And, I DO mean SIGNIFICANTLY!

Two Basic Differences

We have enjoyed all the handheld 3D scanners we own. They include the Sense 1 and Sense 2, the xyzPrinting 3D scanner, four standalone Intel iSense scanners, an HP Notebook with a built-in Intel iSense Scanner and the newer HP Z 3D Scanner. Beyond computer based scanning, our experience also expands to a Sony Xperia XZ1, which is terrific for scanning people and several iPhone and iPad apps. Every one of them is useful at some level.

But, the Matter and Form is totally unique in TWO important differences.

Difference 1: Control, Control and Control!

I mentioned earlier that we were not, initially, able to immediately benefit by obtaining the Matter and Form 3D scanner in time for our 3D Immersion Week. That is because that week is packed with all new experiences for our cadets and it appeared that scanning with the Matter and Form was going to be a long process.

What I didn't know at the time is that how long a scan takes is under OUR control. It's simply a matter of trading speed for higher "Point Cloud" resolution.

All full color 3D scans consist of a Point Cloud that controls the underlying shape and the color image called a 'Material'. One set of cameras captures the point cloud and another captures the color image covering the final rendered object.

Here is an example of the "Point cloud". (Note also multiple test scans listed to the left of the MF Studio screen.)

|

| Point Cloud |

|

| Mesh Material Applied |

Difference 2: Iterative Scanning (Adding scans to improve coverage and quality)

Secondly, scanning is NOT limited to a single all-or-nothing pass. This HUGE! If you have ever used a handheld 3D scanner you, too, have had the experience of trying to capture everything in a single session hoping that one false move doesn't throw you into the frustrations of the "Lost Tracking" wilderness! Even when successful, we are rarely able to scan ALL 3D sides of an object with a 3D scanner in a single scan. In fact, I don't recall a single instance of having been able to do so until obtaining the HP Z 3D scanner. (But, experience with the HP Z scanner, while so promising, has been initially frustrating in that once tracking is lost, it seems very difficult to recover.)

The Matter and Form's software, however, not only allows for multiple scans using different orientations; but, in most cases, easily merges those scans into a single 3D virtual object. And, you don't even have to do those scans in the same session. We can come back to a saved scan project at any time and add additional scans as we learn more and get better at it. In fact, all of the sample scans I am going to use in this article represent a single scan just to show scan quality. And, in every case, we plan to return to the each of the projects to add additional scans using different orientations to complete the project by adding the top and bottom to the scan list.

We can choose any of the scans or a mix of scans to produce our final result.

Why Our Selected Test Objects Are Important

At this point, I should point out why we are beginning our exploration of all of our scanners with the particular objects we have chosen. After all, tobacco tins aren't exactly an obvious choice. And, neither are the upcoming Sponge Bob Square Pants fish tank ornaments. As unlikely as it may seem they do have two things in common. First, both groups of objects can form 'curated collections'. We will not only scan one tobacco tin; but, multiple tobacco tins dating from the early 1900s. Here is just one example:

|

| Santa Tobacco Tin from Cheinco Industries - Pass One |

And, while Sponge Bob Square Pants fish tank ornaments are still being sold; they, too, form a historic collection, albeit a modern one, that will eventually pass away as the future moves on to other cultural icons.

History is a continuum. So, like the visionary Dr. Henry Chapman Mercer, we want all of our students to understand that what is common today may become VERY rare in the not-to-distant future.

The other thing they have in common, although for different reasons, is that they are difficult to scan.

In fact, I suspect that none of the handheld scanners will be able to capture the tobacco tin sample above. That is because the underlying shape of these uniformly round tins are too smooth. Distinctive features work best for hand held scanners.

The Sponge Bob figures present their own challenges that will require multiple scans using different orientations and locations on the turntable to derive a complete capture with the Matter and Form 3D scanner and should be a challenge for our handheld scanners as well.

Highly Recommend Considering a Matter and Form

This was not intended to be a 'review'. It's simply an introduction to the scanner I will be using in our initial 'Virtual Museum' articles. Even so, I cannot conclude this article without issuing a hearty recommendation for the Matter and Form 3D scanner and hope that you will continue to follow our progress to see why I like it so much.

Subscribe to:

Posts (Atom)